Automatic cut to length line or banking line

A flat sheet of material is not actually produced by a mill as a flat sheet. In reality, a flat sheet of material starts its life as part of a coil of material. A Cut-To-Length Line / Blanking Line will uncoil the material, level it, and then cut it to the required length and stack it. The end product produced by a Cut-To-Length Line / Blanking Line is a flat sheet of material cut to a very precise length tolerance. When considering a Cut-To-Length / Blanking Line and the proper line configuration for your application, there are several variables you should consider. The thickness of the material, the type of material, length of the sheets to be produced, as well as annual volume to be processed all influence the line configuration and capabilities required for a successful installation. Light Gage Systems typically process material up to 0.138” (3.5 mm) thick, while Medium Gage Systems process material up to 0.315” (8 mm) thick.

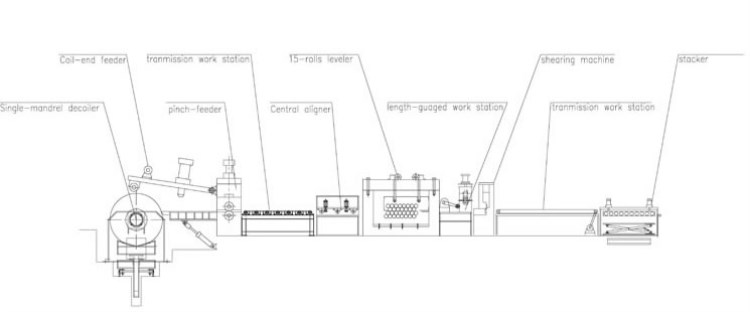

The without loop pit Cut To Length Lines can do uncoiling, leveling, measuring, cross-cutting to length and stacking work. It mainly includes uncoiler, leveler, measuring encoder, shearer, conveyor, stacker, hydraulic system, pneumatic system and electrical system, etc., the line can make sure of accurate feeding and shearing. It can be widely used in cold or hot rolling carbon steel, tinplate, stainless steel and all the other kinds of metal materials with surface coating.

Cut to length line is controlled by PLC system. It has PLC controlled the length measurement. The information of length, shearing numbers and speed can be input to the PLC systems. When the need shearing number is reached the line can stop automatically. The line speed can be adjusted, It has a encoder with high precision, and whole line can work automatically and operate easily, smooth sheet can be made.

Technical process flow:

Coil car-----uncoiling---straightening ----shearing machine-----stacking and piling system

Coil cut-to-length lines work by taking metal coils or rolls from a metal mill and turning them into flat metal sheets of your specifications. Metal coils or rolls resemble giant paper towels. These rolls are fed into the coil cut-to-length line which unspools, flattens, cuts, and then stacks them as flat metal sheets. Coil cut-to-length lines are an effective tool for producing sheet metal for your business.

cut-to-length lines are powerful yet intuitive machines that can fit in any production plant. We offer thin gauge and heavy gauge cut to length line, each suited for specific workloads. Contact us to find the machine that best fits your company.

1. Cut to length Machine (Thin Gauge Line)

Our Thin Gauge line can process different gauges steel in different widths. Product is purchased for its powerful strength and for resistance against corrosion that ensures long lasting service. The machine is customizable as per the specification of our clients. Ultimate goal of our company is to provide innovative products to our esteemed clients.

Features

Works with the powerful hydraulic system

High efficiency

Different sizes and capacity range available

High reliability

2. Cut to length Machine (Thick Gauge Line)

Cut to length Machine (Thick Gauge Line) we offer is capable of processing different gauges with different width ranges. We use our infrastructure facility and hi-end equipments in creation process as well as in installing the product. Our product has robust construction and latest technology is made to face the different working problems. Quality and standard checks are strictly performed on our product before releasing to our valued customers.

Features

Cut to length lines varied from 500 mm to 1500 mm width

Coil thickness varies from 1 mm to 10 mm(In case of different machine) ( CRC, HR, & S.S. Material)

Weight of Coil varies from 3.0 ton to 30 tons

Operation :Hydraulic Power and Pneumatic Clutch

Construct : Made up of EN-31 material roller, hardened gears etc.

Control Line : Electrical Stopper & Servo Motor based.

Control Line Encoder : PLC Based

Cut To Length Line are available in a wide range based on sheet thickness to meet the demands of our customers. By offering the qualitative range, we promise to provide best solutions for clients demand. Our product found application in various recognized metal cutting industries.

Tel:+86 0317-5670260

Whatsapp:+8617832978885 +8618803375788

Fax:+86 0317-5670259

Email:Web@Geitgroup.com

Address:Room711,Culture building, Beijing Road, Yunhe District, Cangzhou City, Hebei,China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours