High Precision Q195 / Q235 Straight Seam Welded Tube Mill Line

This unit is especially for producing tubes within diameter of Φ50.8mm~Φ165mm and thickness of δ2.5mm~7.1mm(square tubeδ≤5.0mm) in a high speed of 20-60m/min.The rolling speed is directly determined by the welded tube thickness. This straight seam welded tube mill support Q195,Q235 carbon steel and Brinell hardness will be ≤60°.

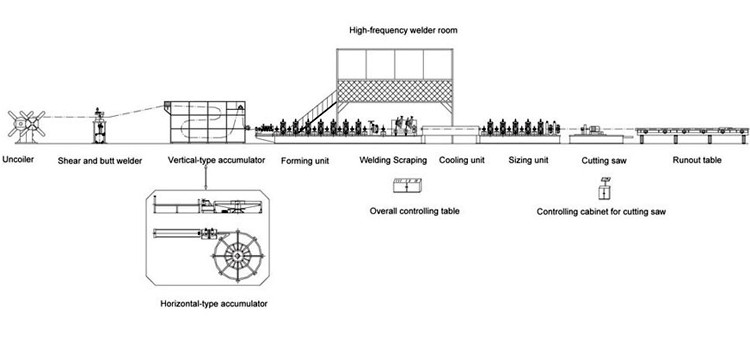

Straight Seam Welded Tube Mill Line working flow:

Raw material (steel strip coil) →decoiler→flattening→powerful leveling →shear and butt-welder→horizontal type accumulator→passively leveling→forming machine→high frequency welding →remove the burrs outside→eddy current flaw detector→spraying cooling →sizing machine→straightening→fixed length cutting →run out table→finished tube

The main components in High precision straight seam welded pipe mill line

1. Uncoiler

The function of this part is to separating the steel strip coil and become to the raw material to roll forming .The steel strip coil will be brought in to the below of the double-drill uncoiler, hydraulic cylinder support the steel strip coil to the centre of the double-drill uncoiler , double-drill uncoiler began moving to hold the steel strip coil, coil car fall off by hydraulic cylinder and go back.

2. Flattening and powerful leveling machine

The function of this part is to separating the front head of steel strip on the uncoiler,also reversed bending the steel coil head to adjusting it’s character of inner curl. Steel strip will enter into the flattening machine by dynamic rubber roll. Flattening machine equipped with one set of pinch roll device and five roll leveling device ,there is one pairs centring device in front and behind it.

(Flattening machine)

3. Shear and butt-welder machine

The function of this part is using hydraulic knife to cutting the irregular part in the front and end of the steel strip through the motor controlled by the human. Adjusting the size of the welding seam, translation hydraulic cylinder moving it to the welding position, two welding platen pressing it than moving the welding gun to the position of welding seam. Opening the motor ,welding and connecting two steel strip by using carbon dioxide arc welding ,polishing and flattening the welding seam by human, so the machine can working continuous. Shear and butt-welder is consist of :electric control operating table ,hydraulic station,welding machine,pinch system,lathe bed system(lathe bed and washer adjusting device),centring system(steel strip end fixed and front head of steel strip translation device ),crane system ,cutting system(cutting device and cutting platen) and welding system(welding tractor and welding platen). Working flow: end of the steel strip enter into the position before cutting –fixed the end of the steel strip-cutting the end of the steel stirp-front head of steel strip enter into the position before cutting- fixed the front head of steel strip –crane moving –adjusting the washer-cutting the front head of steel strip-crane moving –left and right platen fall off-welding –each part back to original position.

4. Horizontal accumulator:

The function of this part is to storing a mount of steel strip to insure the machine working continuous when the steel strip on the shear and butt-welder..

5. Forming machine:(adjusting by worm and worm shaft)

The function of this part is to make the steel strip become to the tube blank by forming rollers

6. Guiding ,extruding, scraping:

(material of extruding roll: H13 heat-resisting, no magnetic)

(scraping : exchange the scraper knife quickly ,different tube diameter choose different tool bit)

The function of this part is to centring the welding seam and guiding the tube blank to extruding device, so the welding seam will be closed before welding . Use planer tool to remove the crater to insure the welding surface is smooth.

7. sizing machine:(adjusting by worm and worm shaft)

The function of this part is used to finishing the tube blank from the forming machine, so the tube size can meet the physical dimension customer required.

8. Water cooling system:adopt water tank spraying type to make sure the tube blank is cooling enough . length of water tank is 6

9. Roughly straightening device:(two sets)

The function of this part is to straightening the finished tube to achieve the ideal glancing flatness. (single side ,four roll, two sets)

10. Computer cutting saw:

The function of this part is to cutting the length of finished tube as customer wanted, have the function of accumulative total for length and amount. Transmission by gear rack ,guide rail choose Thomson profile rail type.

11. Run out table:(double side)

The function of this part is convey the finished tube, equipped with dynamic roll. Double side kick out the tube, can take the waste tube to another way. Length:20M

double side type

.jpg)

Tel:+86 0317-5670260

Whatsapp:+8617832978885 +8618803375788

Fax:+86 0317-5670259

Email:Web@Geitgroup.com

Address:Room711,Culture building, Beijing Road, Yunhe District, Cangzhou City, Hebei,China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours