HSAW welded pipe and tube making machine

The steel coil is unfolded , leveled and sent to the forming machine in certain angle by releated equipment. Continual round pipes are formed in the certain angle with the principle of three-roll rolling machine. Continual spiral welding seams are welded by submerged-arc welding machine.

According to the different functions of our products, the spiral welded pipe mills are divides in to API standard model, national standard model and special purpose model. API standard model mainly produces the delivery pipe for petroleum or natural gas (long distance).Thereby,the material and quality of the steel pipe need to be very good. The requirements for mill equipment and testing equipment are also very high. National standard model produces the pipe used for short distance delivery of natural gas or water, the pipeline construction in the city, the structure pipe, column pipe and so on. The requirements for the material and quality of the steel are also very high, second to that of API standard. Special purpose mill is used for some special purposes. For example, our company developed the special 60~214 mill aiming at the function of petroleum filter.

The specification of our products is fromΦ9 0 toΦ3500. The thickness of the wall is from 1mm to 25.4mm. The material of our products is from Q235 to X80. Besides, special material such as the stainless steel is included. And all of them cover all our mills.

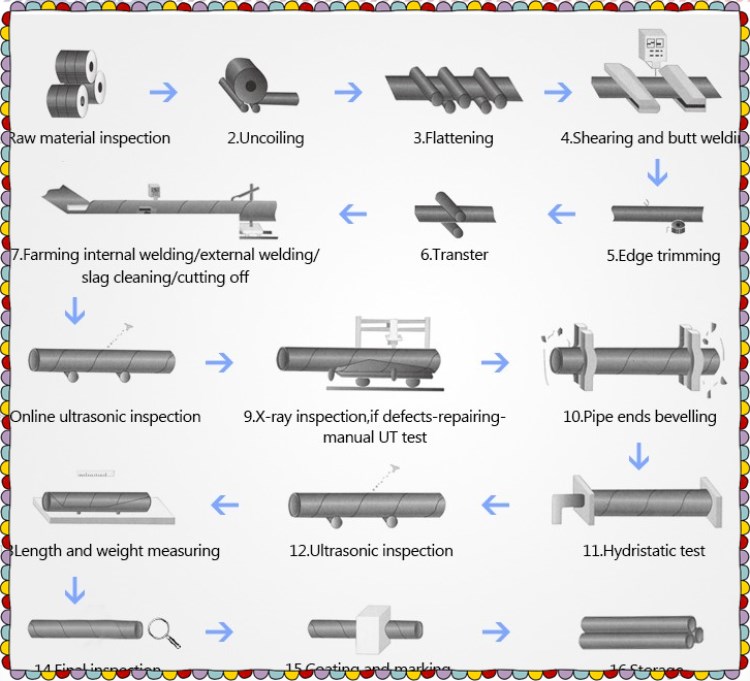

HSAW welded pipe and tube making machine production process:

Loading coil-uncoiling-leveling-cutting and coil welding-circle shear-edge milling machine-main driver–prebending and guide board-forming-internal welding-external welding-tracking and cutting off-extracting-cutting to be alignment-hydrotester-pipe ends facing&chamfering-X ray inspection-UT inspection-spraying-collection of the finished products

Technical parameter:

|

Product Name |

|

|||

|

Size |

OD |

159--3020mm in Theory |

||

|

Thickness |

4--25mm in Theory |

|||

|

Length |

Usually 6~12 Meters, 20 Meters Max in Theory |

|||

|

Standard |

SY/T5037 SY/T5040 GB/T9711 API5L EN10208 ASTM A252 JISA5525 |

|||

|

Material |

Chinese Grade |

Q235,Q345,S245,S290,S320,S360,S390,S415,S450 |

||

|

Foreign Grade |

ASTM |

Grade A,Grade B,X42,X46,X52,X56,X60,X65,X70 |

||

|

EN |

S185,S235JR,S235JO,E335,S355JR,S355JO L245,L290,L320,L360,L390,L415,L450 |

|||

|

Usage |

Used For Water, Sewage, Gas, Stream, Combustible Fluids(Petroleum and Gas) |

|||

|

Ends |

Beveled (Can be Protected By Plastic Caps or Steel Rings According to Your Requirements)Also We Can Weld Flanges on the Pipe Ends Plain Ends |

|||

|

Surface |

Bared Or Paint With Oil, Bitumen,1-3 layer PE |

|||

|

Inspection |

With Chemical Composition and Mechanical Properties Testing; Hydrostatic Test, Dimensional and Visual Inspection, Also With Nondestructive Inspection |

|||

|

Technique |

Hot Rolled and SSAW or DSAW |

|||

|

Package |

Package With Steel Strip When O.D≤273MM, Otherwise In Bulk. |

|||

|

Date of Delivery |

According to The Specifications And the Quantities, Time Begin When We confirm the Date of the Earnest or L/C |

|||

|

Method of Payment |

T/T L/C West Union |

|||

|

Method Of Delivery |

Terms According To the for International Trading, |

|||

|

Others |

N/A |

|||

The pipe making machine consist of:

Uncoiler

Pinching & leveling machine

Manual/Electrical roll

End - Cutting & butt-welding machine

Rotary shear

Delivery machine

Guide board

Forming unit

Front bridge

Inside/outside welding device

Rear bridge

Flying saw cutter

Buried parts

Hydraulic system

Electric system

Inside/outside welder

Butt-weld car

Plasma cutter

Weld flux processing device

Beveling & end-facing machine

Hydraulic tester

Finishing equipment

Tel:+86 0317-5670260

Whatsapp:+8617832978885 +8618803375788

Fax:+86 0317-5670259

Email:Web@Geitgroup.com

Address:Room711,Culture building, Beijing Road, Yunhe District, Cangzhou City, Hebei,China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours