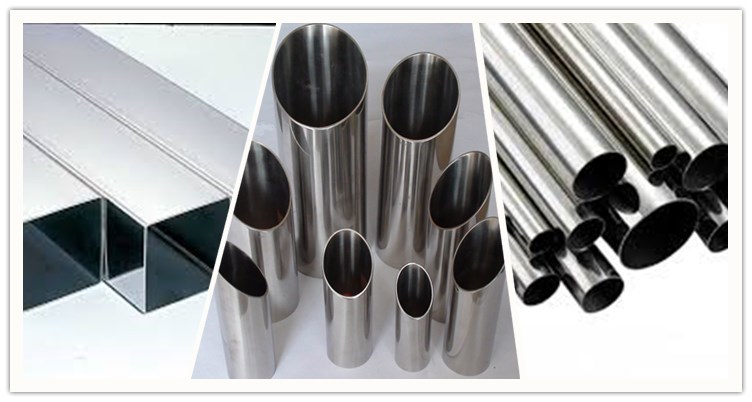

SS Tube and Pipe Mill Equipment

We have gained expertise in offering a comprehensive range of Stainless steel Tube and Pipe Mill Equipment to our esteemed clients. Manufactured using superior quality raw material procured from the reliable vendors of the market, these products are widely used in various industries such as Oil and Drilling Industry, Piping Industry, Paper Mills, Steel Tube Mill Industry and TMT Plants industry. Owing to their robust construction, longer functional life and excellent performance, these products are highly appreciated by the customers.

The Tubes/Pipes made in this machine basically uses cold roll forming technology to give desired shape to the raw material strip. The strip grade can be 200, 300, 400 series. The roll formed open section of the strip is welded longitudinal by TIG welding process or in High Speed by Solid State High Frequency Induction Welder. Then the Welded Pipe/Tube seam is finished on line by tool or grinding process. The Pipe/Tube is then cooled down by coolant water. The Sizing section of the Tube/Pipe Mill shapes the Tube/Pipe for desired perfect shape. Shapes of the Tube/Pipe made by this machine depends on the desire of the customer. Machine has the capacity to make different shapes of pipe like Round/Circular, Rectangular as well as Square. There is a cutting section in the machine which is used to slice the Pipe/Tube. The cutting section cuts the pipe/tube for desired length online by automatic cutting car. The run out table takes out the cut length pipe/tube in the collection pit. After all these process the manufactured products are taken out in the market for desired use.

SS Pipe and Tube Manufacturing Process:

Rolling and welding

Firstly, the stainless steel strips are made to gone through various quality checks and are trimmed at edges. They are then fed to the tubes mill, The strips pass through the number of rollers as per the required size. In the tubes-mill, the strip is gradually converted into the tubular shape. The fitted welding machine is then used to weld trim edges of the strip using TIG welding process. The scraps and inside weld bead are removed instantaneously by the Tibo machine. In this way, rolled pipes and tubes are formed.

The cleaning and heating phase

The rolled stainless steel pipes thus manufactured are cut to the required lengths depending upon the industrial demand. These stainless pipes and tubes are then subjected to cleaning to remove the dirt. Further, a heat treatment is given to these rolled pipes and tubes to remove the stresses that may occur due to welding and formation processes. Heat treatment is given on the continuously rolling hearth furnace. The furnace is fitted with temperature recorders and controllers. After the heat treatment process, the SS tubes and pipes are straightened and subjected to pickling for removing scales from the surface.

Cold-drawing process

In some cases, the required size may not be obtained from the mill directly. Then, the cold operation process can be used to obtain the desired size. In cold drawing process, the tubes or pipes are coated with oxalic and soap solution. This solution acts as a lubricant to reduce friction while cold drawing operation. In the cold drawing process, the tube or pipe is drawn over the bench using Die plugs.

Finishing process

The drawn-out tube or ss pipe is then subjected to cleaning, heat treatment, pickling and straightening. The computerized ink jet marking machine is used to do the marking on the finished pipes or tubes. The pipe or tube is marked with grade of material, size, heat number and the stamp of third party inspection before passing on to stainless steel pipe exporters. The stainless tubes or pipes thus produced will undergo certain testing and quality checks. This process is followed by proper packing and dispatch. There are numerous numbers of stainless steel pipe applications, these pipes and tubes are used thereafter for.

The machine can produce the stainless steel pipe, carbon steel pipes, copper pipes, not only for round pipe, but also the rectangular/ square pipe etc.

Perfect after-sale service system:

1). Offering the welding technology for free.

2). We can help you train your staff.

3). We can offer different technology engineers, such as engineer for pipe making machine and engineer for polishing machine etc.

4). Plant Designing and calculate the power consumption.

5). We will send Engineer to help you install the machines, and guide your staff on site, until your workers can produce the qualified pipes.

6). The warranty period is one year, except man-damage. If you have any question in using the machines, you can call us or send email, and we will solve the problem for you asap.

7). We can introduce the high-quality raw material suppliers, and guide you how to distinguish the quality of raw materials.

8). We can accompany you to see the running machine, making you have a general idea about the full project, and absorb some successful experience.

9). We supply the pre-sell and after-sell service. Pre-sell service: Workshop design, and production output design After-sell service: Installation and training, and the skilled engineer for working.

Tel:+86 0317-5670260

Whatsapp:+8617832978885 +8618803375788

Fax:+86 0317-5670259

Email:Web@Geitgroup.com

Address:Room711,Culture building, Beijing Road, Yunhe District, Cangzhou City, Hebei,China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours