Automatic stainless steel tube making machine with mature technology:

Stainless steel pipe making machine is designed for manufacturing stainless steel straight welded pipe for metallurgy, construction, transportation, and machinery and vehicle industries. It adopts long steel strip as the material to manufacture steel pipes according to requested size by cold rolled forming and argon arc welding method. To be specific, the stainless steel pipe production line can produce round pipe, square and rectangular tube, as well as section steel through cold rolled forming and TIG welding technology.

The machine is designed featuring easy and safe to operate, low maintenance, and cost reduction, reducing and high production. The stainless steel pipe, which allows flatting, forming, welding, annealing, polishing, sizing, straightening, finishing, cutting, and unloading at one time for production.

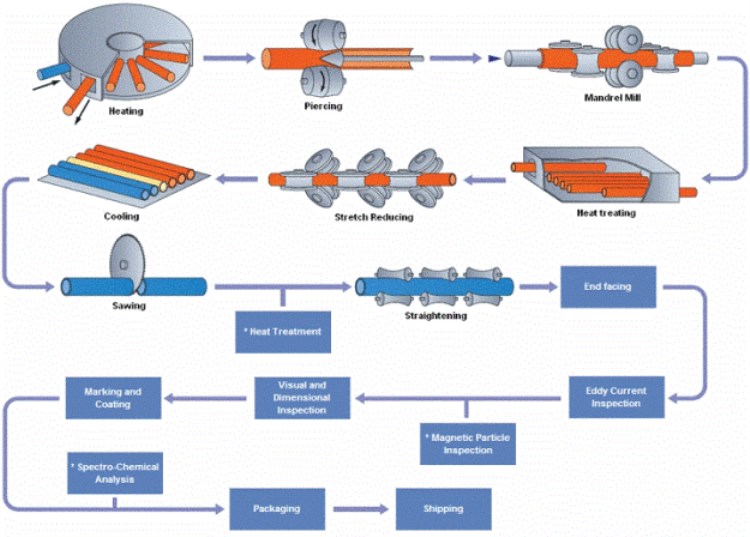

Process Flow of Stainless Steel Tube Making Machine

Slit Coil → Un-coiler → Forming → TIG Welding → De-beading → Grinding → Sizing → Annealing → Sizing →Cutting → Run out Table → Pipe collecting and packaging

Main components of stainless steel tube making machine:

| (1) Uncoiler | (2) Forming Section |

| (3) TIG Welder | (4) Electric Control Panel |

| (5) Welding Torch Stand | (6) De-beading Section |

| (7) Seam Grinding | (8) Initial Sizing |

| (9) Online Bright Annealing | (10) Final Sizing |

| (11) Cutting Sation | (12) Run out Table |

Applications of Stainless Steel Tube Making Machine

1. Industrial Steel Pipes

2. Decoration Pipe

Parameter of stainless steel tube making machine for industry usage:

|

Title |

GTS30 |

GTS40 |

GTS50 |

GTS60 |

GTS80 |

GTS100 |

GTS110 |

|

OD(mm) |

Φ5-20 |

Φ8-45 |

Φ25-76 |

Φ50.8-114 |

Φ89-159 |

Φ114-219 |

Φ114-325 |

|

WT(mm) |

δ0.3-1.2 |

δ0.3-2.5 |

δ0.5-3 |

δ0.6-3.5 |

δ1-4 |

δ1.5-5 |

δ1.5-8 |

|

Speed(m/min) |

2-9 |

0.5-7 |

0.5-4 |

0.5-4 |

0.5-3 |

0.5-2 |

0.4-1.7 |

|

Drive Motor(KW) |

4 |

7.5+6 |

11+8 |

15+11 |

18.5+15 |

22+15 |

22+18.5 |

|

Seam grinding unit |

3KW×1 |

3KW×N |

3KW×N |

3KW×N |

3KW×N |

3KW×N |

3KW×N |

|

Transmission |

Gear box |

Gear box |

Gear box |

Gear box |

Gear box |

Gear box |

Gear box |

|

M/C length(mm) |

5 |

7.8 |

8.5 |

9 |

13 |

14 |

17 |

|

Remark |

|

||||||

Parameter of stainless steel tube making machine for industry usage:

|

Title |

TS30 |

TS40 |

TS50 |

TS60 |

TS80 |

|

OD(mm) |

Φ4-15 |

Φ6-32 |

Φ8-48 |

Φ38-76 |

Φ50.8-114 |

|

WT(mm) |

δ0.2-0.8 |

δ0.17-1.2 |

δ0.18-2 |

δ0.4-2.5 |

δ0.5-3 |

|

Speed(m/min) |

2-12 |

2-16 |

2-16 |

3-13 |

3-11 |

|

Drive Motor(KW) |

4-3 |

5.5 |

8 |

11 |

15 |

|

Seam grinding unit |

3KW×1 |

3KW×N |

3KW×N |

3KW×N |

3KW×N |

|

Transmission |

Gear box |

Gear box |

Gear box |

Gear box |

Gear box |

|

M/C length(mm) |

2.4 |

6 |

7 |

7.5 |

8.5 |

|

Remark |

|

||||

Tel:+86 0317-5670260

Whatsapp:+8617832978885 +8618803375788

Fax:+86 0317-5670259

Email:Web@Geitgroup.com

Address:Room711,Culture building, Beijing Road, Yunhe District, Cangzhou City, Hebei,China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours