GEIT HG76 is designed for gantry type to welding pipe of Φ10mm-Φ89 mm with thickness of 1.0mm-3.0mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into pipe, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, sizing or shaping and finally on-stream cutting of endless tube in measured lengths. It is quite suitable for thoese want to operate a pipe making mill, For this type machine can supports much more types of welded pipe in large range pipe diameters, and also it could make pipe in a very high speed of 20-80m/min.

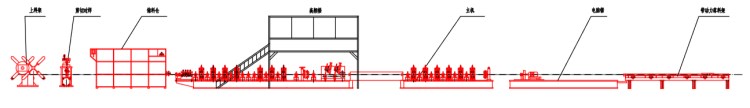

Steel coil→→ Double-head uncoiler →→Strip-head Cutter and welder→→Spiral Accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller)+ Deburr frame →→Cooling unit →→ Sizing unit and straightener →→Flying saw under computer-control →→ Run-out table

|

Main elements of HG76 welded pipe making mill: |

|

|

Double head uncoiler |

1 |

|

Hydraulic shearing and manual welding machine |

1 |

|

Coiler feeder to accumulator |

1 |

|

Accumulator |

1 |

|

Forming and sizing mill |

1 |

|

F5-200kw solid state H.F welder |

1 |

|

Electric control system |

1 |

|

CNC flying friction saw |

1 |

|

Roll out table |

Steel frame, if you need the automatic one then we can change for you |

|

Tech service |

The tech team needs to stay at customer factory 6 months, training customers till everything works well. And the all fee will be covered by customer. |

Tel:+86 0317-5670260

Whatsapp:+8617832978885 +8618803375788

Fax:+86 0317-5670259

Email:Web@Geitgroup.com

Address:Room711,Culture building, Beijing Road, Yunhe District, Cangzhou City, Hebei,China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours