Frontal-swinging Spiral Welded Pipe Line

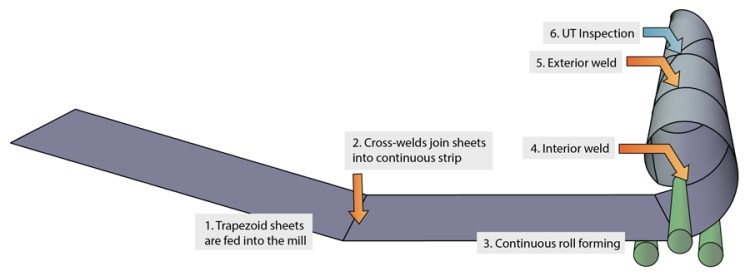

Spiral welded pipe machine, also called SSAW pipe mill. It is used to manufacture big diameter pipes by spiral welding method. first use the decoiler to uncoil and level the steel coil and send the strip to forming machine by certain angle, then bend the pipe by certain angle based on three-roller forming principle, at last to weld the spiral welding seam by the submerged arc welder.

Working process of Spiral Welded Pipe Line:

GEIT design and manufactur a range of types of SSAW pipe mill according to customer requirement. Ourφ630~φ3520mm Frontal-swinging Spiral Welded Pipe Line is used in the highest grade of steel coil X52 (Max) with thickness:δ=3-10mm and width:B=700-1650mm. Through the uncoiling, leveling , cutting ,forming , welding process, the φ630~φ3520mm Frontal-swinging Spiral Welded Pipe is produced. And then through chamfering, hydrostatic test, UT detection, X-ray detection etc ,the finish machine can satisfy the API-5L、ASTM、IS standard. Electronic control system adopts siemens PLC automatic control system,digital display system, DC speed control system of Continental European,variable-frequency speed control system of Delta etc. The SSAW pipe line has outstanding features like simple operation, convenient maintenance and high reliability.

SSAW pipe mill specification:

|

Main specification of diameter of φ630~φ3520 spiral welded pipe Line |

||||

|

S/N |

Item |

Specification |

||

|

Raw material specification |

||||

|

1 |

Raw material OD |

φ1200~φ1800mm |

||

|

2 |

Raw material ID |

φ500~φ780mm |

||

|

3 |

Coil width |

700~1650mm |

||

|

4 |

Material thickness |

3~10mm |

||

|

5 |

Coil material |

Q235,Q345B |

||

|

6 |

Curved teeth |

≤20mm/5m |

||

|

7 |

The tower coils |

≤60mm |

||

|

8 |

Max weight |

15 Ton |

||

|

Finished Pipe specification |

||||

|

9 |

Pipe diameter range |

φ630~φ3520mm |

||

|

10 |

Material thickness |

3~10mm |

||

|

11 |

Pipe length |

8~12(土0.5)m |

||

|

12 |

Forming angle |

40 o ~80o |

||

|

13 |

Transmission speed |

0.5~3m/min |

||

|

Welding part |

||||

|

14 |

Welder |

Take single wire automatic submerged arc welding |

||

|

15 |

Welding speed |

0.5~2.0m/min |

||

|

16 |

Inner and outside welder |

Take single wire automatic submerged arc welding |

||

|

17 |

Inner and outside welding speed |

0.5~1.5m/min |

||

|

18 |

Swing degree |

38 o ~82 o |

||

|

19 |

Rear axle swing degree |

土1.5 degree |

||

|

20 |

Year production |

25000 Ton / year |

||

Tel:+86 0317-5670260

Whatsapp:+8617832978885 +8618803375788

Fax:+86 0317-5670259

Email:Web@Geitgroup.com

Address:Room711,Culture building, Beijing Road, Yunhe District, Cangzhou City, Hebei,China

Please feel free to give your inquiry in the form below.We will reply you within 24 hours